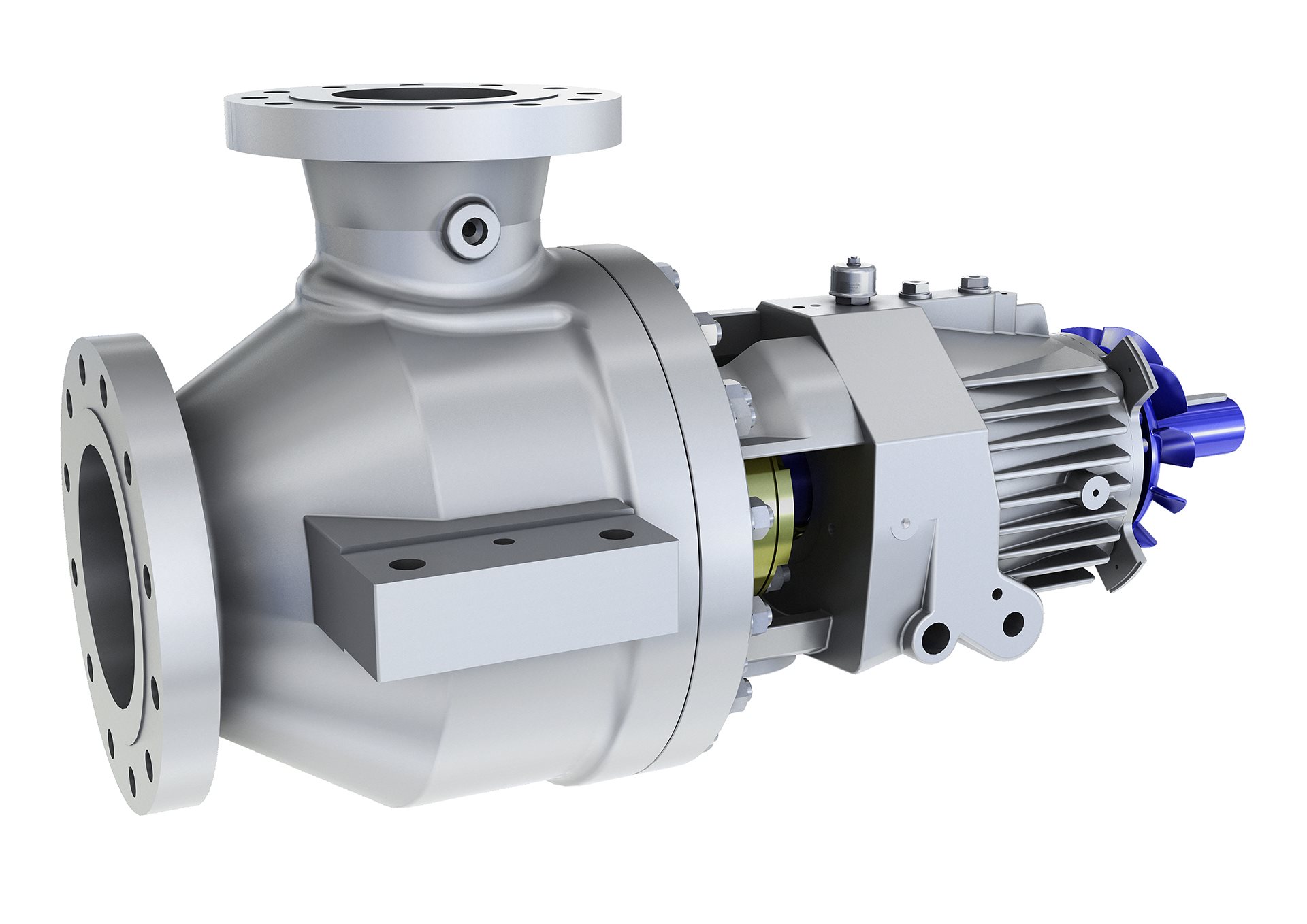

One model, in particular, stands out from the rest: the stainless steel single stage centrifugal pump. What makes this pump unique is its one-piece volute casing, which is produced using an advanced computer-controlled Plasma stamping system. This ensures total quality control during manufacturing, making it a durable and reliable choice for many industries.

What is a Single Stage Centrifugal Pump?

First, let's break down what a single stage centrifugal pump actually is. It's a type of pump that uses an impeller to move liquid through a volute casing, which creates a centrifugal force. This force then pushes the liquid towards the discharge outlet, where it's pumped out.

The main advantage of a single stage centrifugal pump is its simplicity. Since there's only one impeller, it's easy to maintain and repair. They're also efficient in moving large volumes of liquid quickly, making them ideal for many different applications.

Advantages of a Stainless Steel Single Stage Centrifugal Pump

Now that we know what a single stage centrifugal pump is, let's talk about what makes the stainless steel version of this pump so special. Here are a few key advantages:

1. Durable Material: Stainless steel is known for its durability, resistance to corrosion and wear, and its ability to withstand high temperatures.

2. One-Piece Volute Casing: The unique one-piece volute casing produced by the advanced computer-controlled Plasma stamping system ensures that the pump is made precisely and with complete quality control.

3. Easy Maintenance: Since there's only one impeller, maintaining and repairing the pump is relatively simple.

Applications

The stainless steel single stage centrifugal pump is commonly used in a variety of industries but is particularly well-suited for light industry. Here are a few examples of how it can be used:

1. Glasses Lens Manufacturing: The pump can be used to move and recirculate liquids during the lens polishing and coating process.

2. Eyewear Manufacturing: The pump can be used to transfer solvents, coolants, and other liquids used during the manufacturing process.

3. Beverage Industry: The pump can be used to transfer liquids during the brewing process, such as pumping water to the brew kettle.

4. Food Industry: The pump can be used to transfer liquids during food processing, such as pumping liquids to a mixing tank.

In conclusion, the stainless steel single stage centrifugal pump is a durable, reliable, and efficient option for a wide range of applications. Its one-piece volute casing and easy maintenance make it an ideal choice for many different industries, especially light industry. So, whether you're in the glasses lens, eyewear, beverage, or food industry, consider a stainless steel single stage centrifugal pump for your liquid moving needs.