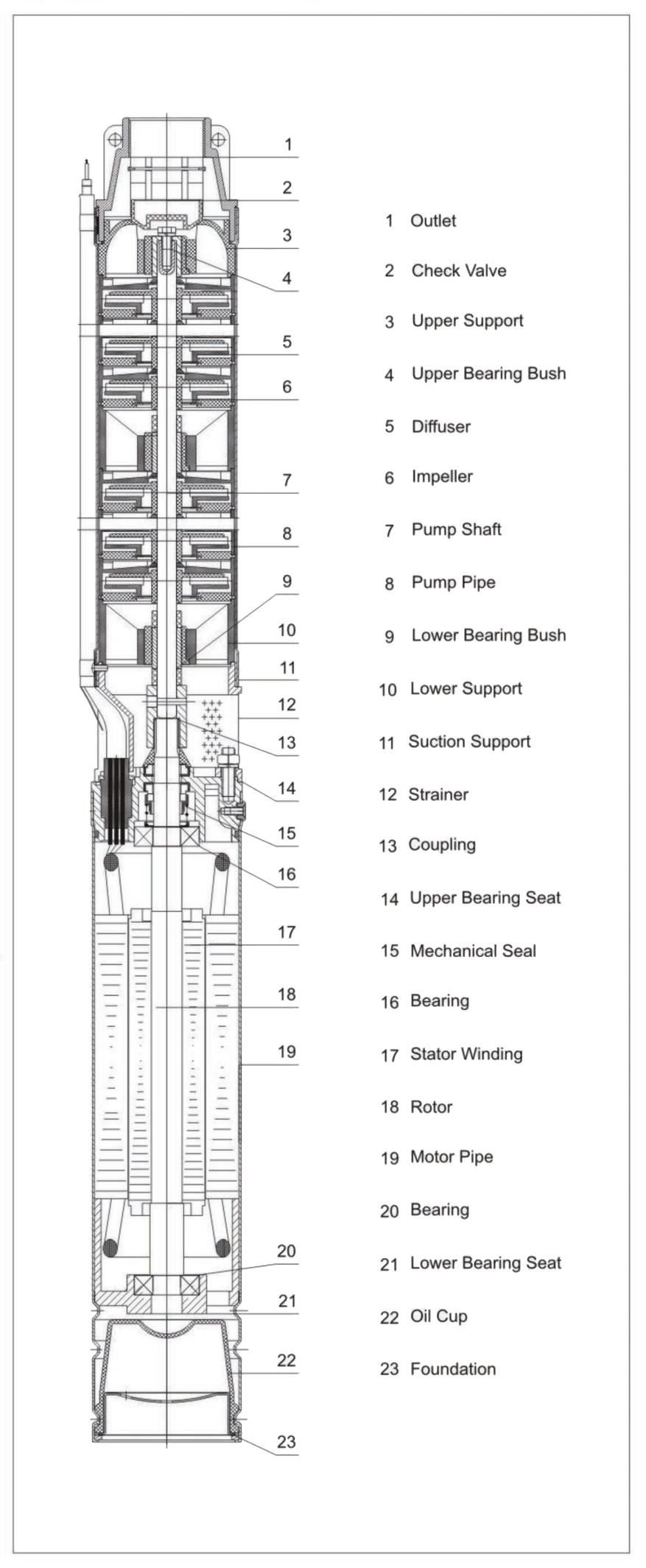

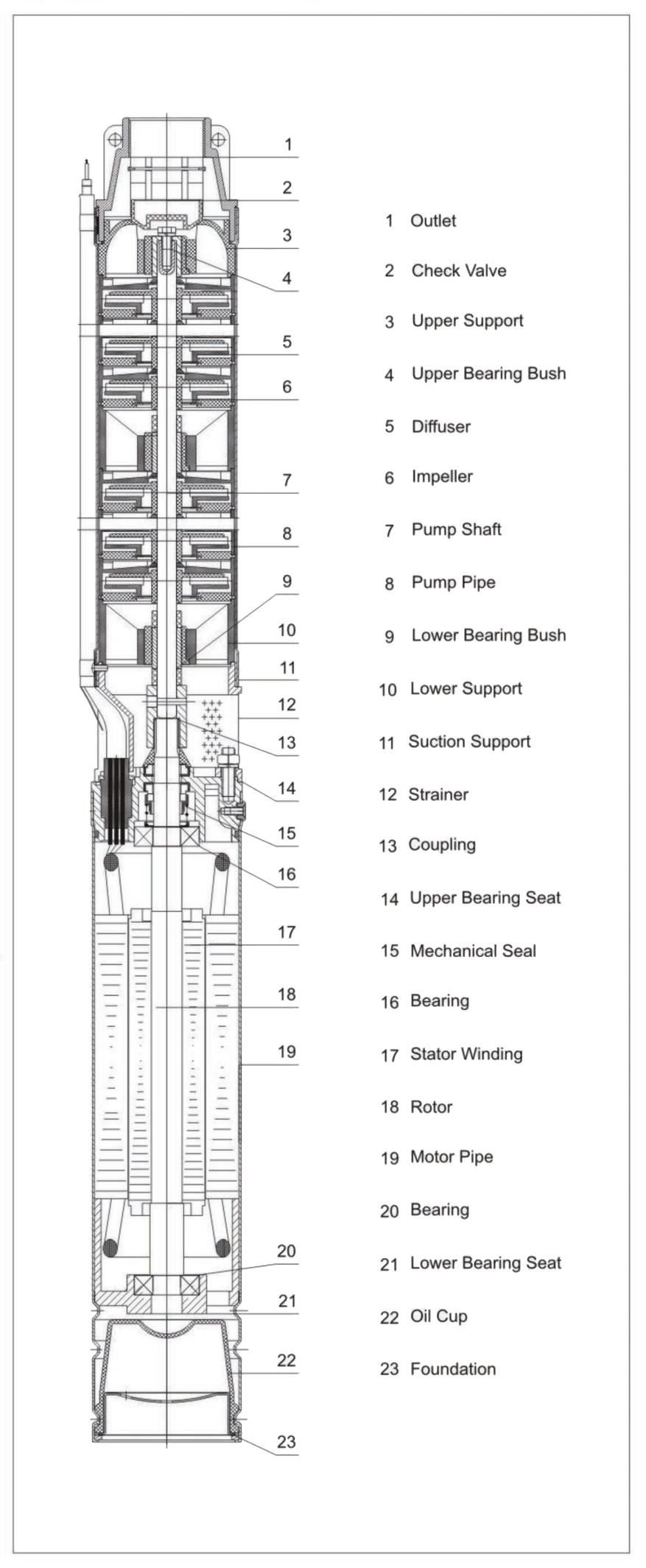

Products Details

Structure description

1. The deep well submersible pump unit for QJ well is composed of four parts: water pump, submersible motor (including cable), water delivery pipe and control switch. The submersible pump is a single-suction multi-stage vertical centrifugal pump: the submersible motor is a closed water-filled wet, vertical three-phase cage asynchronous motor, and the motor and the water pump are directly connected by a claw or single-barrel coupling; equipped with three different specifications. Core cables; starting equipments are air switches of different capacity grades and self-coupled decompression starters, water pipes are made of steel pipes of different diameters and are connected by flanges, and high-lift electric pumps are controlled by gate valves. 2. A rubber bearing is installed in the guide shell of each stage of the submersible pump; the impeller is fixed on the pump shaft with a conical sleeve; the guide shell is integrated with threads or bolts. 3. The upper part of the high-lift submersible pump is equipped with a check valve to avoid the damage of the unit caused by the shutdown. 4. The upper part of the submersible motor shaft is equipped with a labyrinth-type sand control device and two reversely assembled skeleton oil seals to prevent quicksand from entering the motor. 5. The submersible motor adopts water-lubricated bearings, and the lower part is equipped with a rubber pressure regulating film and a pressure regulating spring to form a pressure regulating chamber to adjust the pressure change caused by temperature; the motor winding is insulated by polyethylene, and the nylon sheath protects against consumer water. The connection method of the magnet wire and the cable is according to the QJ type cable joint process. The joint insulation is removed and the varnish layer is removed, and then the joints are connected well, and the welding is firm, and the raw rubber is used to wrap a layer. Then wrap 2~3 layers of waterproof adhesive tape, and wrap 2~3 layers of waterproof tape on the outside or wrap a layer of rubber tape (inside the bicycle) with water glue to prevent water seepage. 6. The motor is sealed with precision stop bolts, and the cable outlet is sealed with a rubber gasket. 7. There is a water injection hole at the upper end of the motor, a vent hole, and a water drain hole at the bottom. 8. The lower part of the motor is equipped with upper and lower thrust bearings. There are grooves on the thrust bearings for cooling, and it is a stainless steel thrust plate for grinding, which follows the upper and lower axial force of the water pump. working conditions

1. QJ type deep well submersible pump power requirements: (1) The rated frequency is 50 Hz, and the rated voltage of the motor terminal should be guaranteed to be a three-phase AC power supply of 380+5% volts (if the user voltage is 660 volts, special orders are required). (2) The load power of the transformer should not exceed 75% of its capacity. (3) When the transformer is far away from the well, the voltage drop of the transmission line should be considered. For motors with a power greater than 45KW, the distance from the transformer to the wellhead should not exceed 20 meters. level, taking into account the line voltage drop. 2. Water quality requirements: (1) Generally non-corrosive clean water. (2) The sand content in water is not more than 0.01% (mass ratio). (3) The pH value of pH is in the range of 6.5-8.5. (4) The chloride ion content in the water is not more than 400 mg/L. (5) The hydrogen sulfide content is not more than 1.5 mg/L. (6) The water temperature should not be higher than 20℃. 3. Wellbore requirements: upright, smooth, without bulge or misalignment of the well pipe, and the inner diameter of the well is not less than the corresponding machine base size. Structure Diagram

Multistage Centrifugal Pump,

High Pressure Vane Pump,

Grundfos Centrifugal Pump,

Self Priming Centrifugal Oil Pump,

Plastic Centrifugal Pump,

Three Screw Pump,

End Suction Back Pull Out Centrifugal Pump,

Mud Pump,

Centrifugal Monoblock Pump,

Horizontal Multistage Centrifugal Pump,