Products Details

Product Introduction

WQ/QG Triple-Reamer Cutting Efficient and Non-Clogging Submersible Sewage Pump is a new type of sewage equipment a cutting system designed and produced on the basis of foreign advanced submersible sewage pump technologies and in accordance with the national standard GB/T24674-2009; Waste submersible motor-pumps. This series of water pumps features these advantages: beautiful appearance, simple structure, strong sewage treatment capacity, high efficiency and energy saving. At the same time it can be equipped with automatic control and automatic installation self-coupling devices So that the pump combination is more excellent with safer and more reliable operation. Working Conditions

1, The medium temperature should not exceed 60℃, the medium density is 1.0~ 1.3kg/dm³, the pH value is within 5~9,and the medium should be free of crystallization; 2. For those pumps without an internal flow circulation cooling system, their motor part out of the liquid surface should not exceed 1/2; 3. Under normal circumstances, the pump must be used within the working lift head range to ensure that the motor is not overloaded, and to use within the full lift head range, it should be noted separately in your order so that the manufacturer can make as required; 4. In the course of running, the pump's motor current should not exceed the motor's rated current. Main Purpose

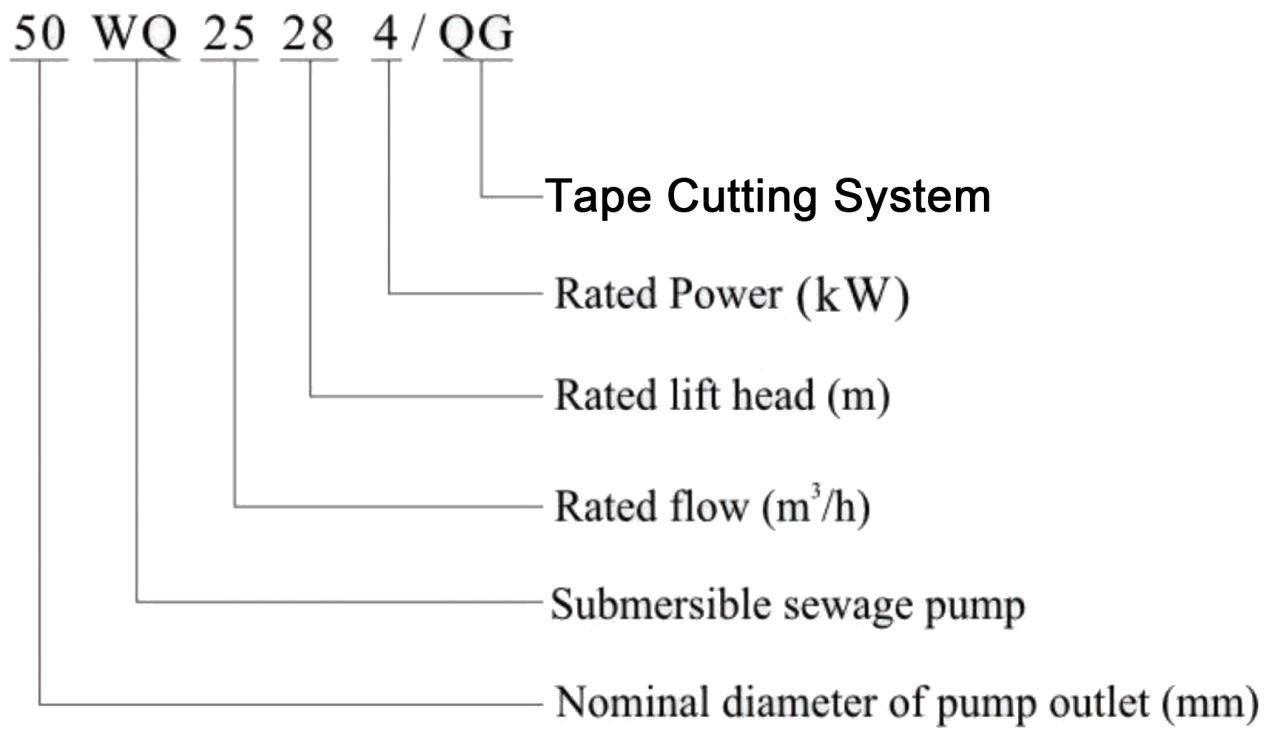

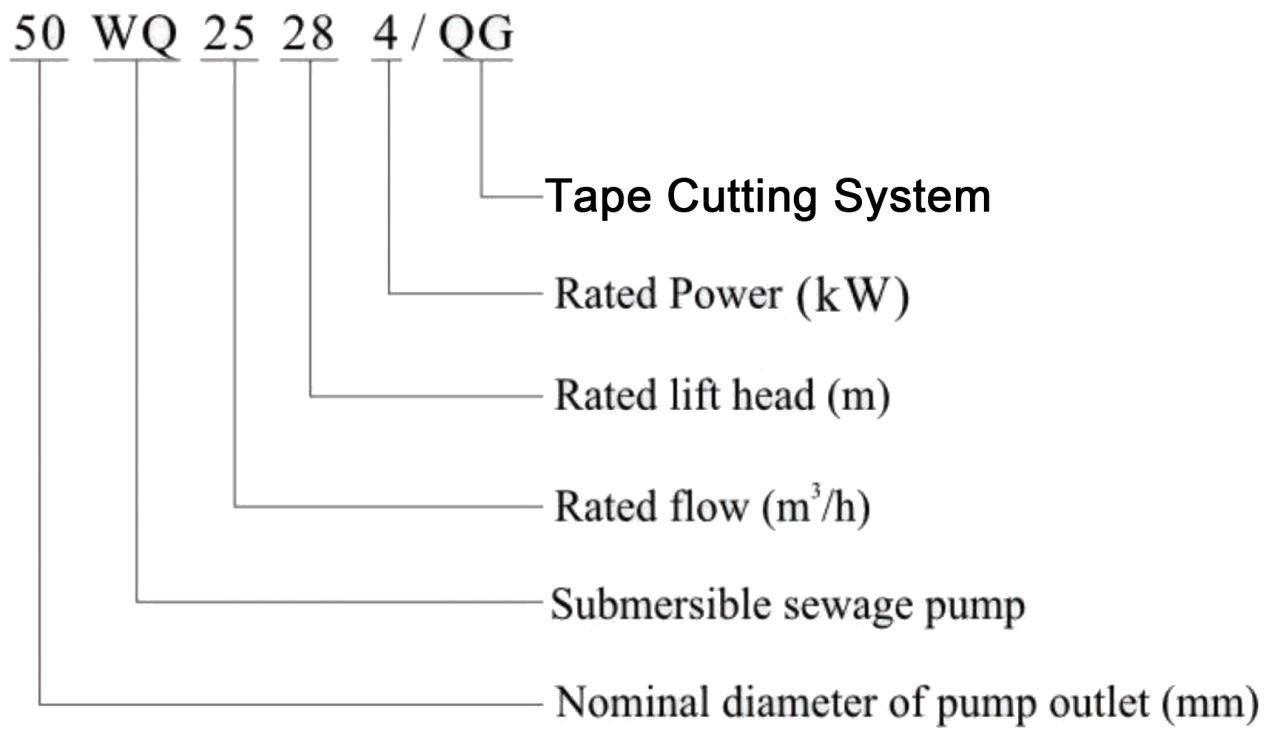

1. Drainage of seriously polluted waste water from factories or commerce; 2. Drainage systems of municipal sewage treatment plants; 3. Sewage drainages stations in residential areas; 4. Water drainage stations of civil air defense systems; 5. Sewage discharged from hospitals or guesthouses; 6. Municipal works or construction sites; 7. Auxiliary systems for exploration or mines; 8. Rural methane tanks and farmland irrigation; 9. Water supply systems of water plants; 10. Various cultivation farms, slaughterhouses, septic tanks, etc. Type Designation

Product Characteristics

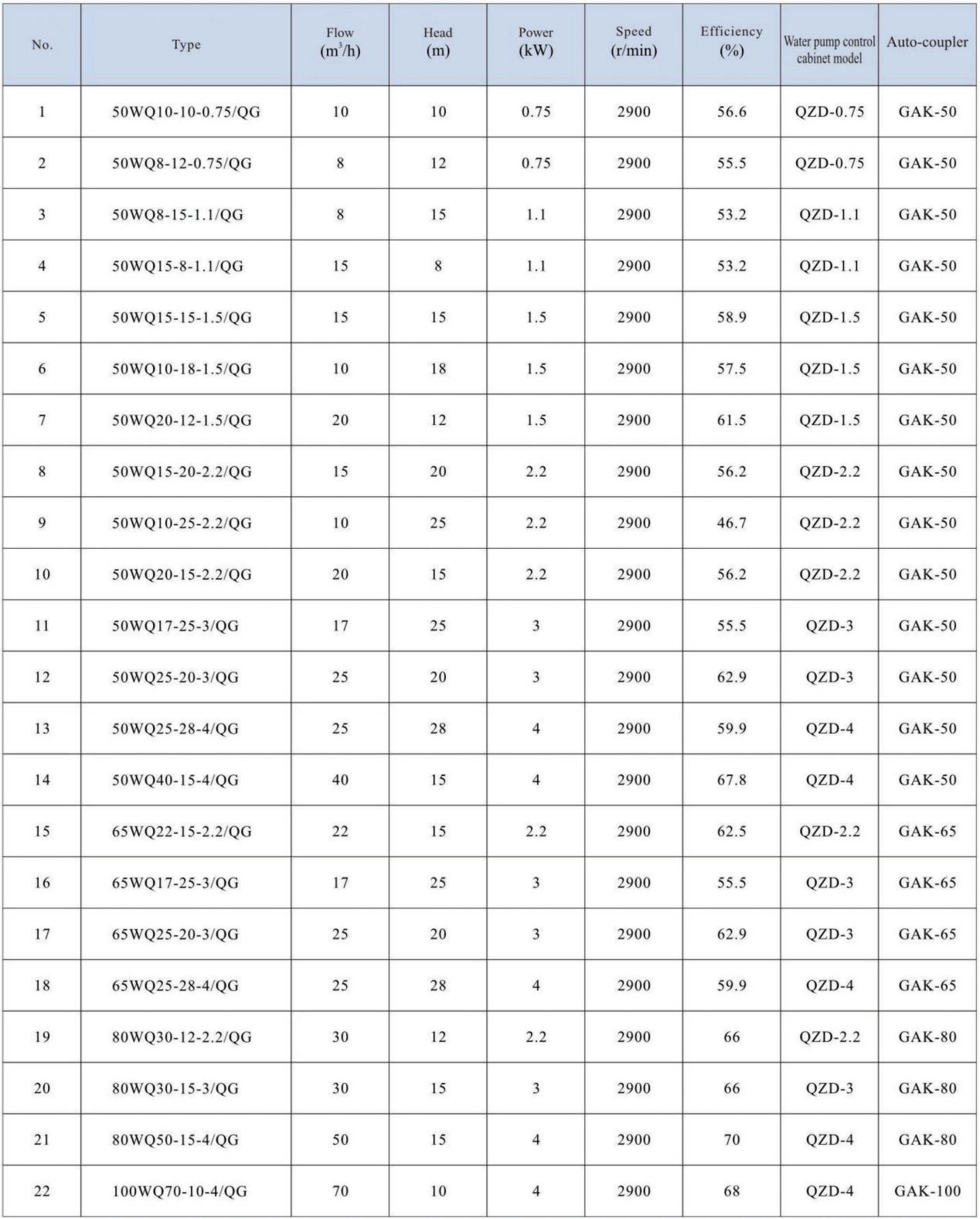

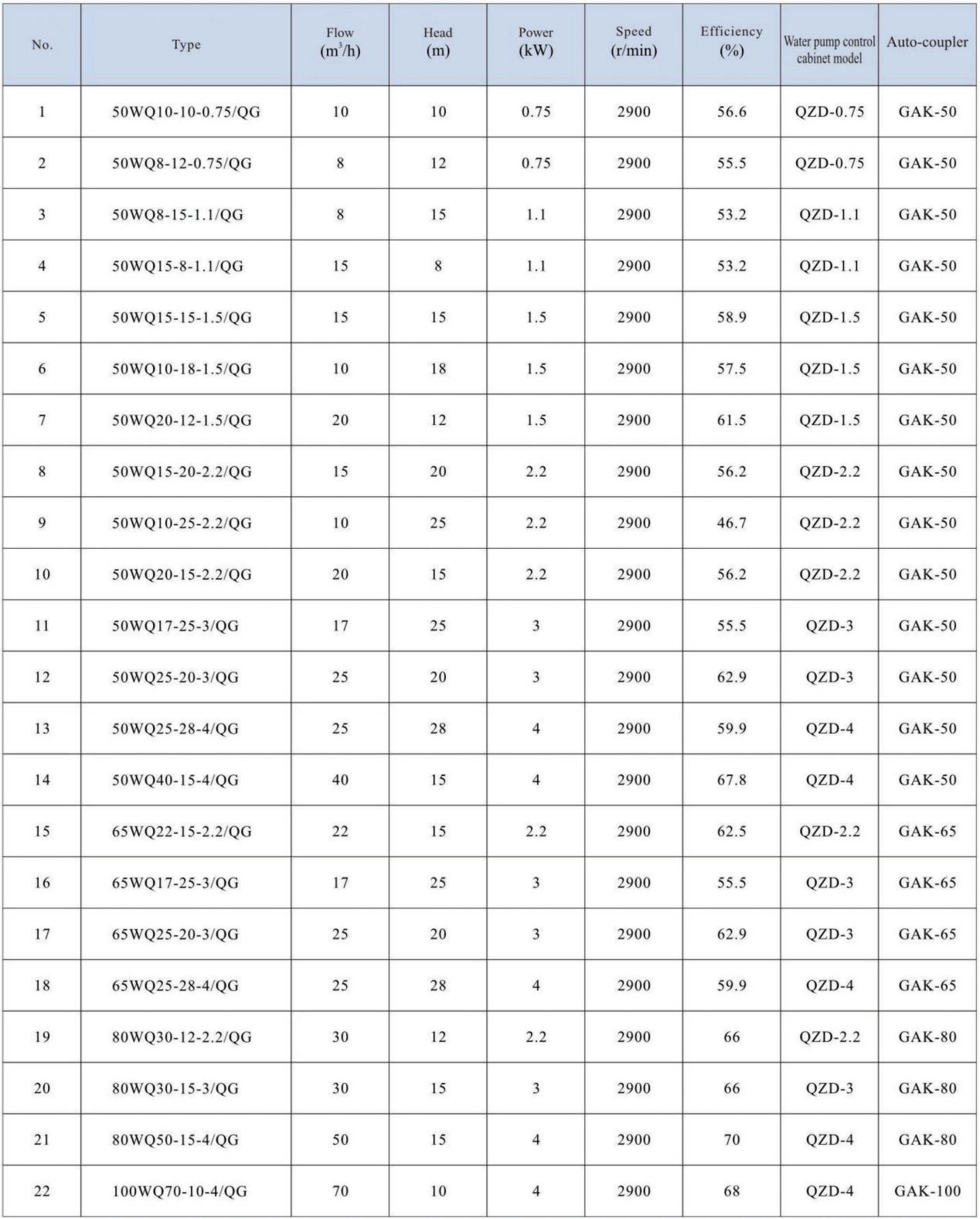

The submersible sewage pump has many advantages, and the most prominent of them is that you can directly put it into water for use. In the absence of a trash rack or if such mounting is inconvenient, however, an ordinary submersible sewage pump is often vulnerable to pump and pipeline clogging caused by big debris in sewage, causing trouble to users. At the same time, when there is too much silt deposition at the sewage sump, an ordinary submersible sewage pump may not be able to run normally and there is a need to spend a lot of human and material resources to clean up. In order to solve the above deficiencies of an ordinary submersible sewage pump, our company developed WQ/QG Triple-Reamer Cutting Efficient and Non-clogging Submersible Sewage Pump. This pump not only has all the advantages of an ordinary submersible sewage pump, but also has the following unique advantages: 1. The pump is equipped with a specially designed debris cutting system which consists of a stainless steel cutting disc and a triple-blade rotary cutter, The cutter works perfectly with the cutting disc,which is able to chop fibers and easily twisted objects, with a good cutting effect and high cutting efficiency (a cutting rate up to 8,700times/min). It can transport long fibers and other twisted media to completely avoid the pump and the pipeline from being clogged by the debris in sewage,so there is no need to mount any expensive sewage trapping and removal devices. At the same time, the extended part of the rotary cutter head can function as a stirrer so that the sewage can be stirred to avoid sludge deposition and ensure the normal operation of the pump. And it's extremely convenient and fast to adjust the cutting system or replace any part of it. 2. Both the cutter and the cutting disc are made of corrosion-resistant precipitation hardening stainless steel and adopt special technical treatment so that the cutter and the blades on the cutting disc can be both hard enough and corrosion-resistant, thus they can be extremely anti-wear and keep sharp for a long time. 3. The impeller and the flow channel on the pump feature an excellent hydraulic performance, high efficiency and minimal loss;the two have a fine size match so that the chopped debris can pass successfully. 4. Thanks to the unique bearing and mechanical seal arrangement, the shaft cantilever is very short while the shaft's stiffness and strength can be high so that the shaft can withstand a large impact load; the shaft's vibration is very small during running so that the mechanical seal's leakage can reduce greatly: the pump adopts high- quality fully sealed self-lubricating bearings with no need for daily maintenance, and they can still have a long life even in the heavy load working conditions when the pump can not chop hard objects. 5. Both the pump side and the motor side are equipped with mechanical seals to achieve reliable double submersible shaft seal protection for the motor. The oil in the oil chamber can adequately lubricate and cool the mechanical seal. 6. The scraping slot set between the cutter and the cutting disc can scrape away the thin and male able debris squeezing between the two to prevent the power from increasing or staling. 7. A dual-rail automatic coupling installation system, which can be supplied as required by users, can bring great convenience to installation and maintenance so that persons do not have to enter the sewage sump for such purposes. 8. A fully automatic safety control cabinet, which can be supplied as required by users, can provide absolute protection for the pump from water leakage, current leakage, overload, over-temperature and others to improve the product's safety and reliability. 9. A float switch, which can be supplied as required by users, can control the pump's starting and stopping automatically according to liquid level changes so that it can be unattended, extremely convenient for use. Performance Parameters

Chemical Pump,

Zoeller Sewage Pump,

Single Screw Pump,

Water-Cooled Vacuum Pump,

Best Sewage Ejector Pump,

Gas Transfer Pump,

High flow rate pump,

Water Tretment Pump,

Portable Fire Pump,

Forced Circulating Pump,